FretHaus Guitar (2024): The Punk Magnet

Sponsored Studio: Gibson Guitar + EMG Hardware

Duration: 16 Weeks

As part of Auburn University's SIGD (School of Industrial and Graphic Design) annual Gibson-sponsored studio/show, FretHaus, my class and I were tasked with not only designing - but actually building - an electric guitar whose theme relates not only to our own musical identity but to a greater relatable market.

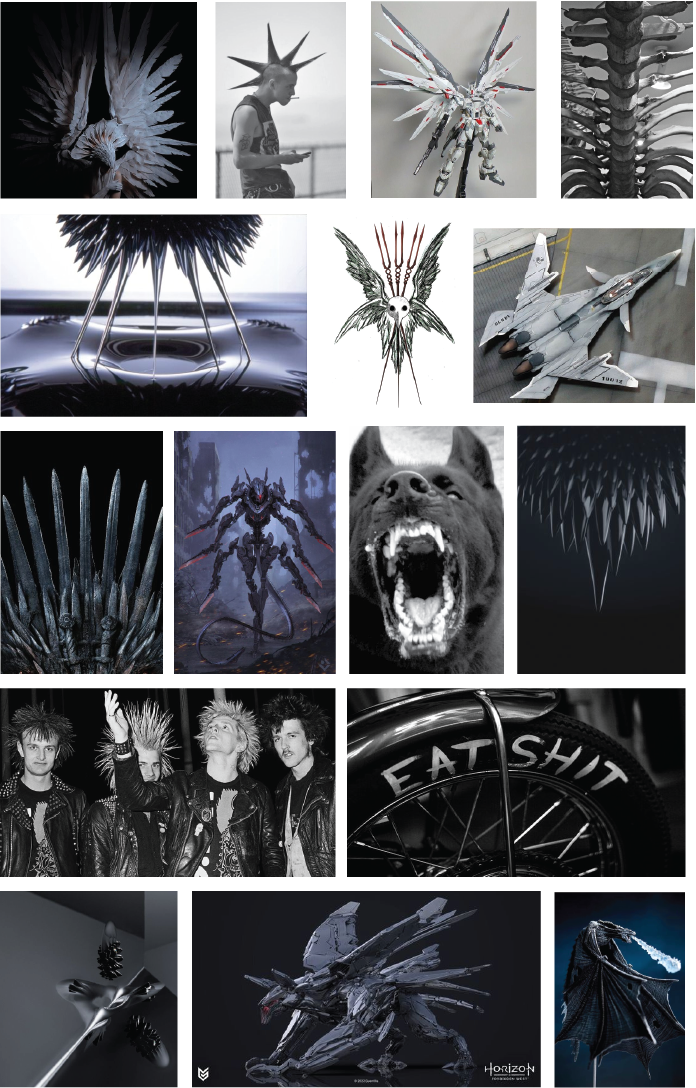

Inspiration

As a frequent attendee of the local DIY underground house shows, I asked myself:

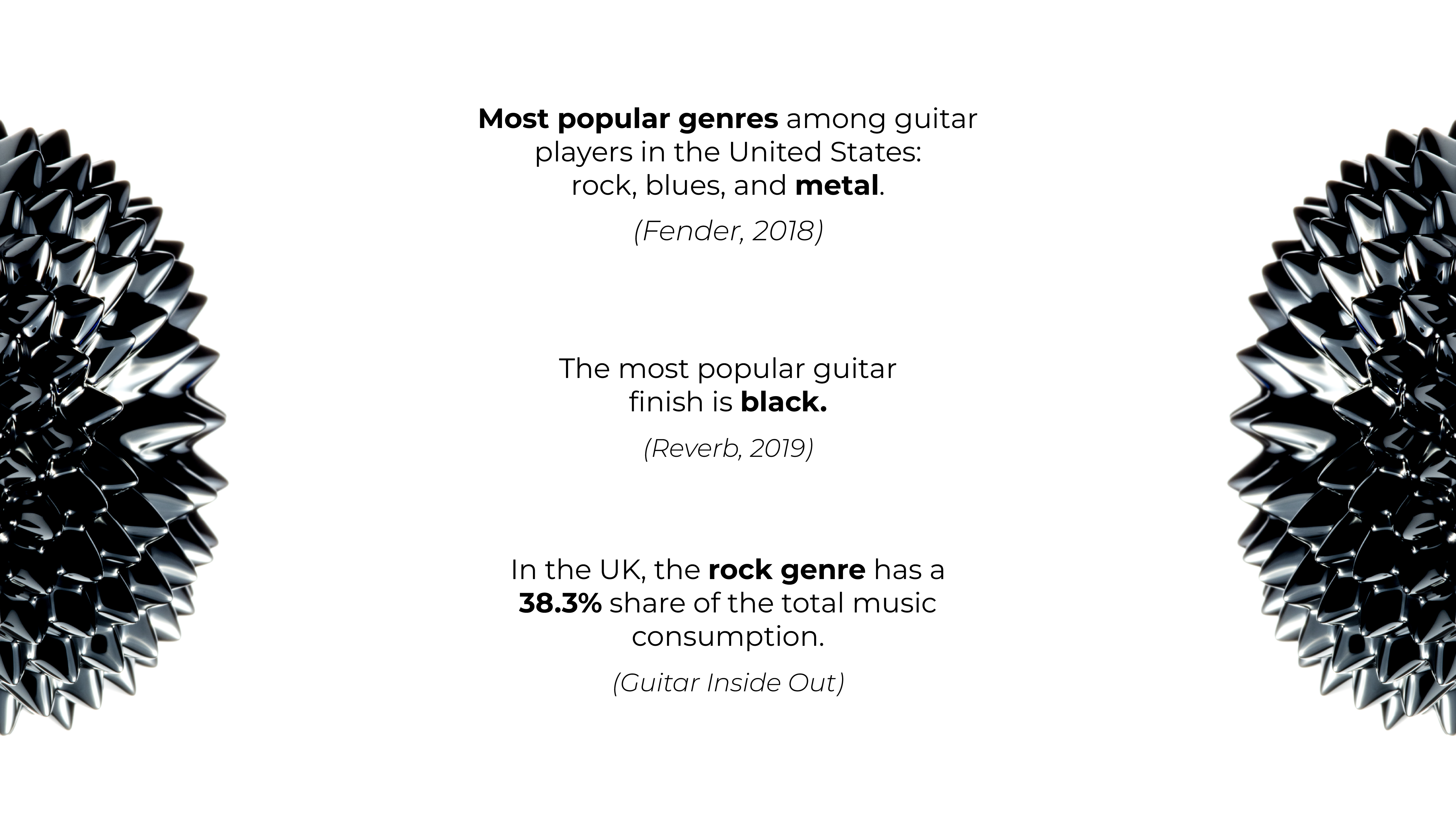

What design aesthetic best represents the punk counter-culture music scene?

The answer?

FerroFluid

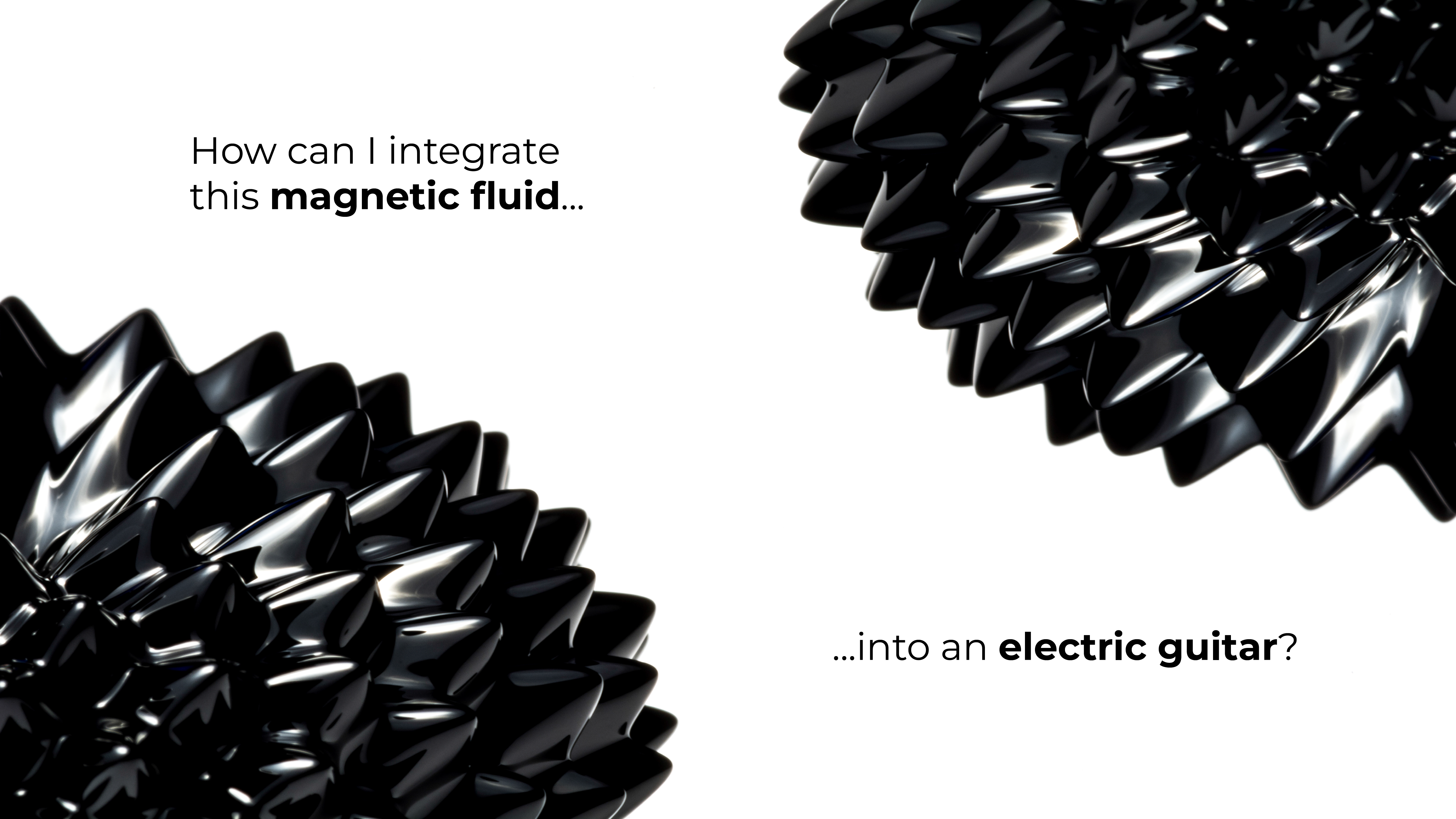

What is FerroFluid?

A ferrofluid is a liquid which becomes highly magnetized in the presence of a magnetic field. The distinctive ‘spikey’ shape of a magnetized ferrofluid is caused by the need to find the most stable shape in order to minimize the total energy of the system, an effect known as the normal-field instability.

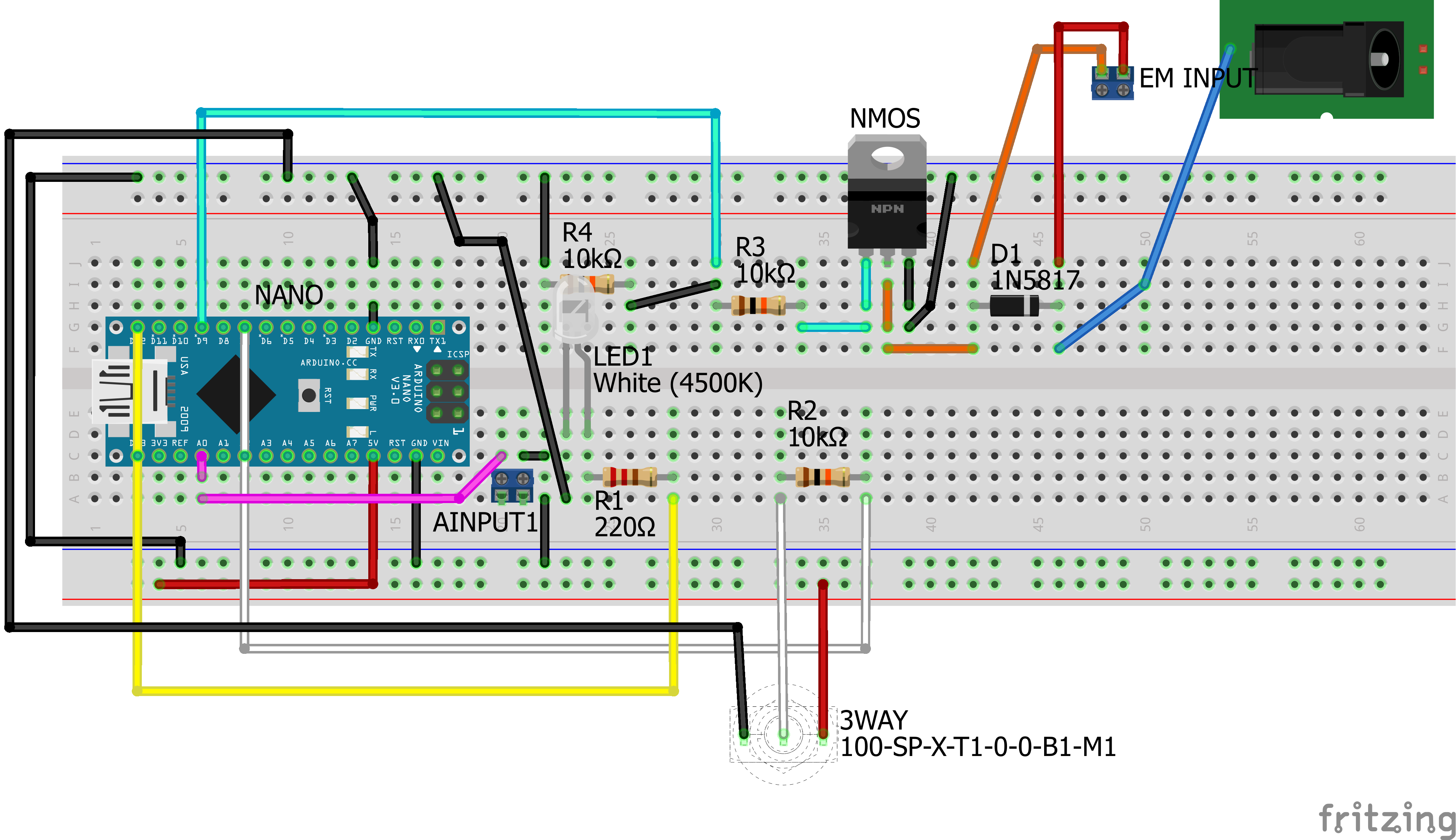

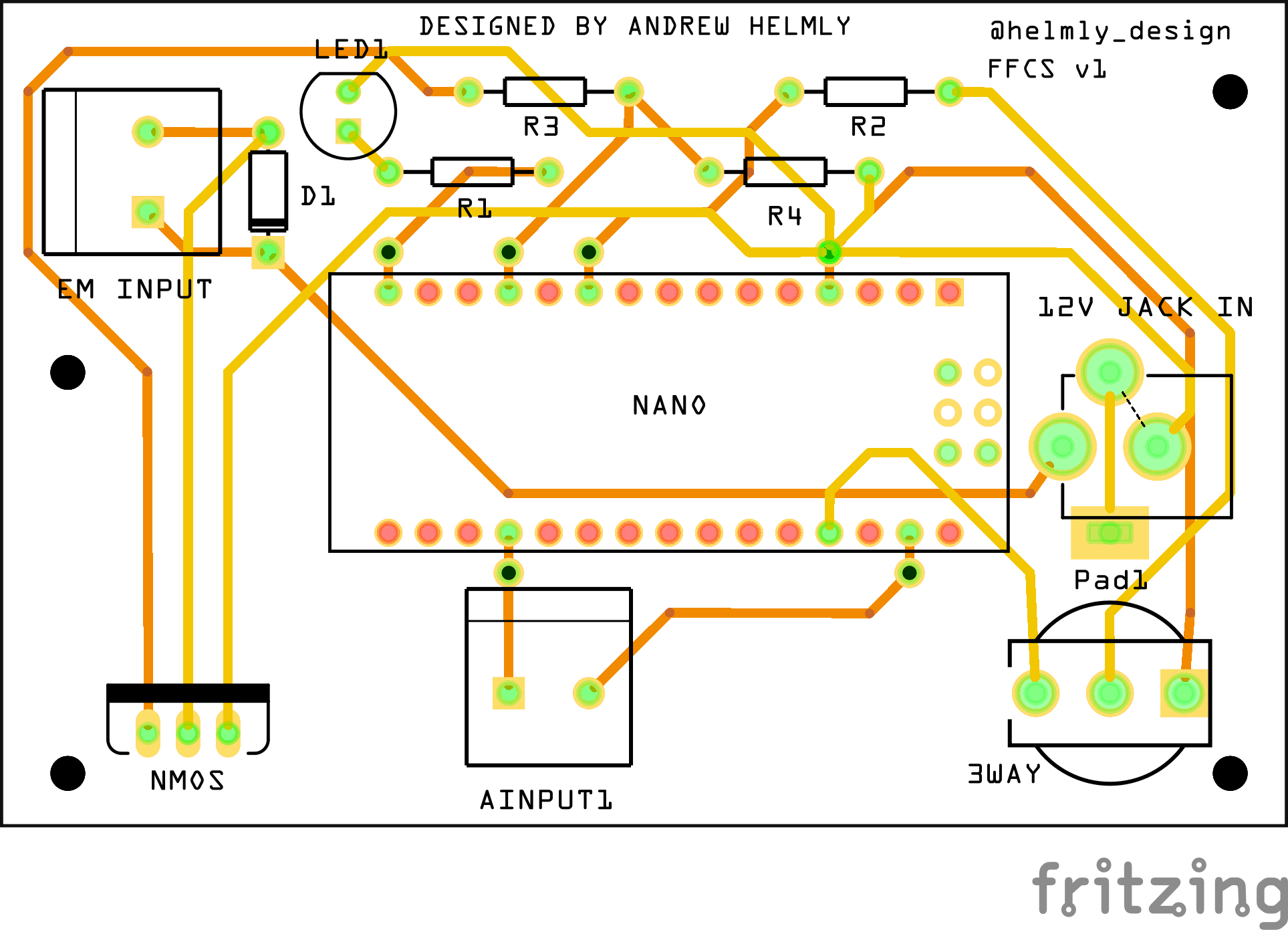

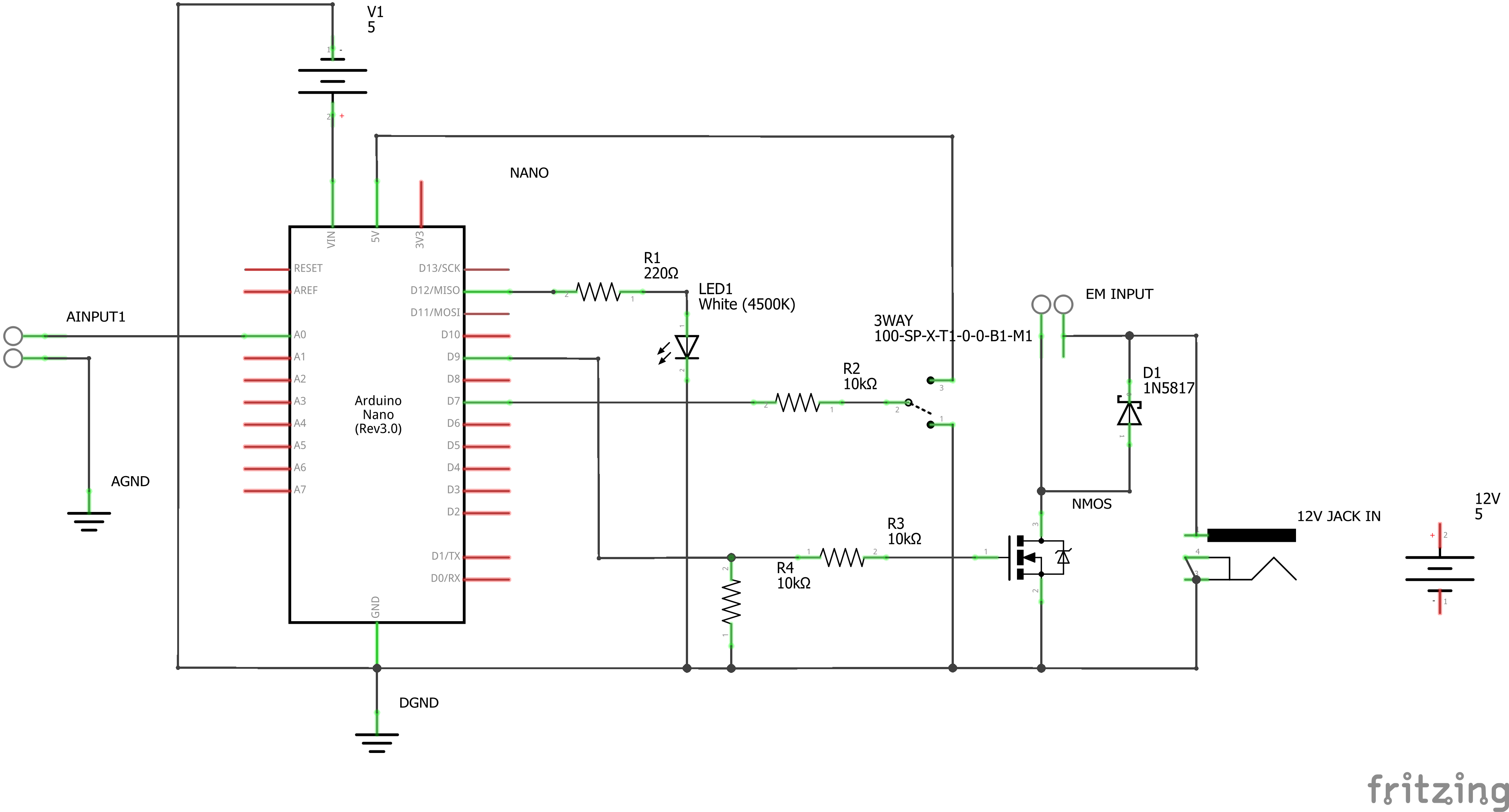

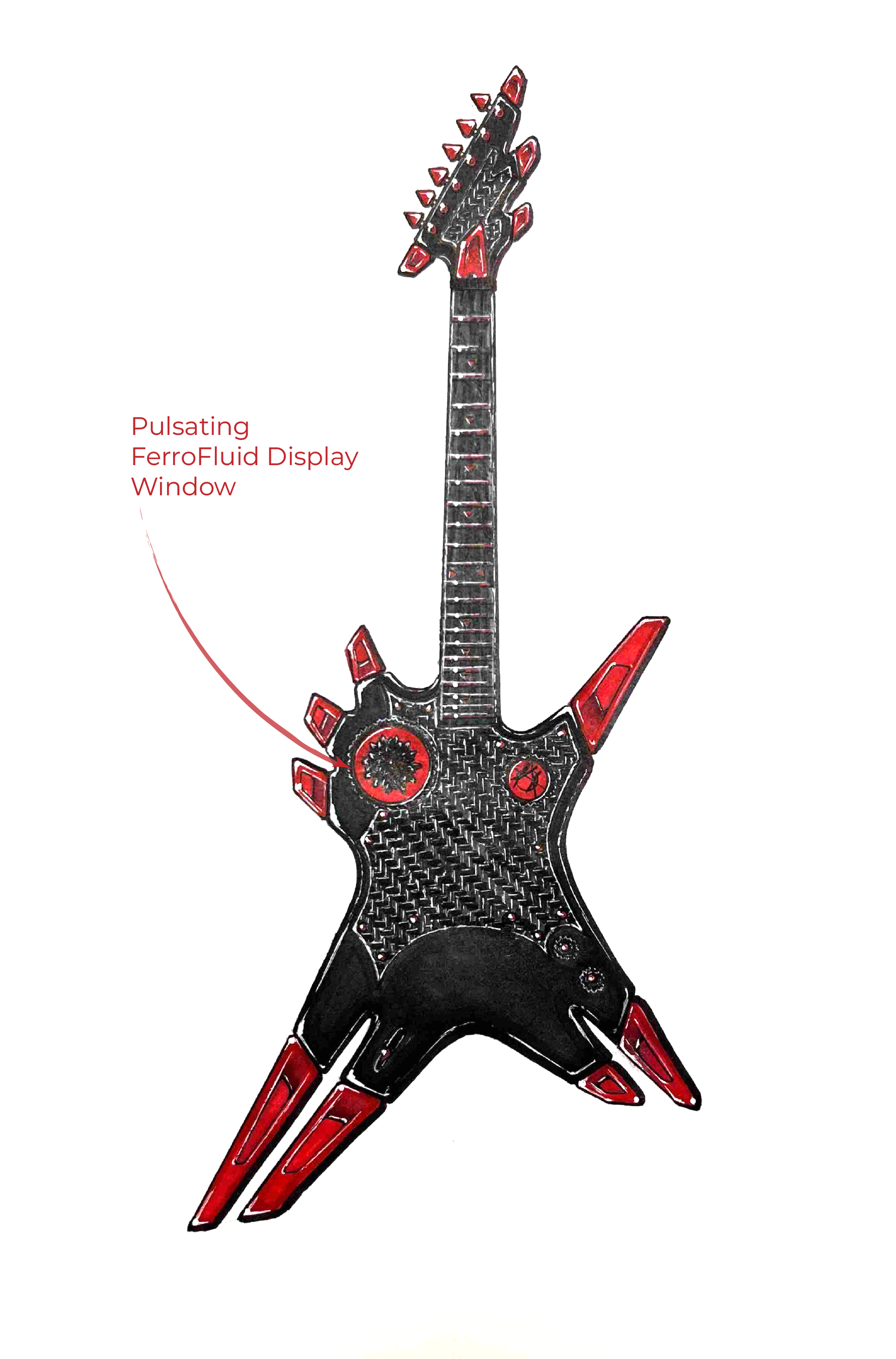

Creating the FerroFluid Control System (FFCS)

After months of programming, wiring, and testing...

I was able to tap into the guitar's electronics to create an electromagnetically-controlled system able to pulse a window of FerroFluid within a viewing window.

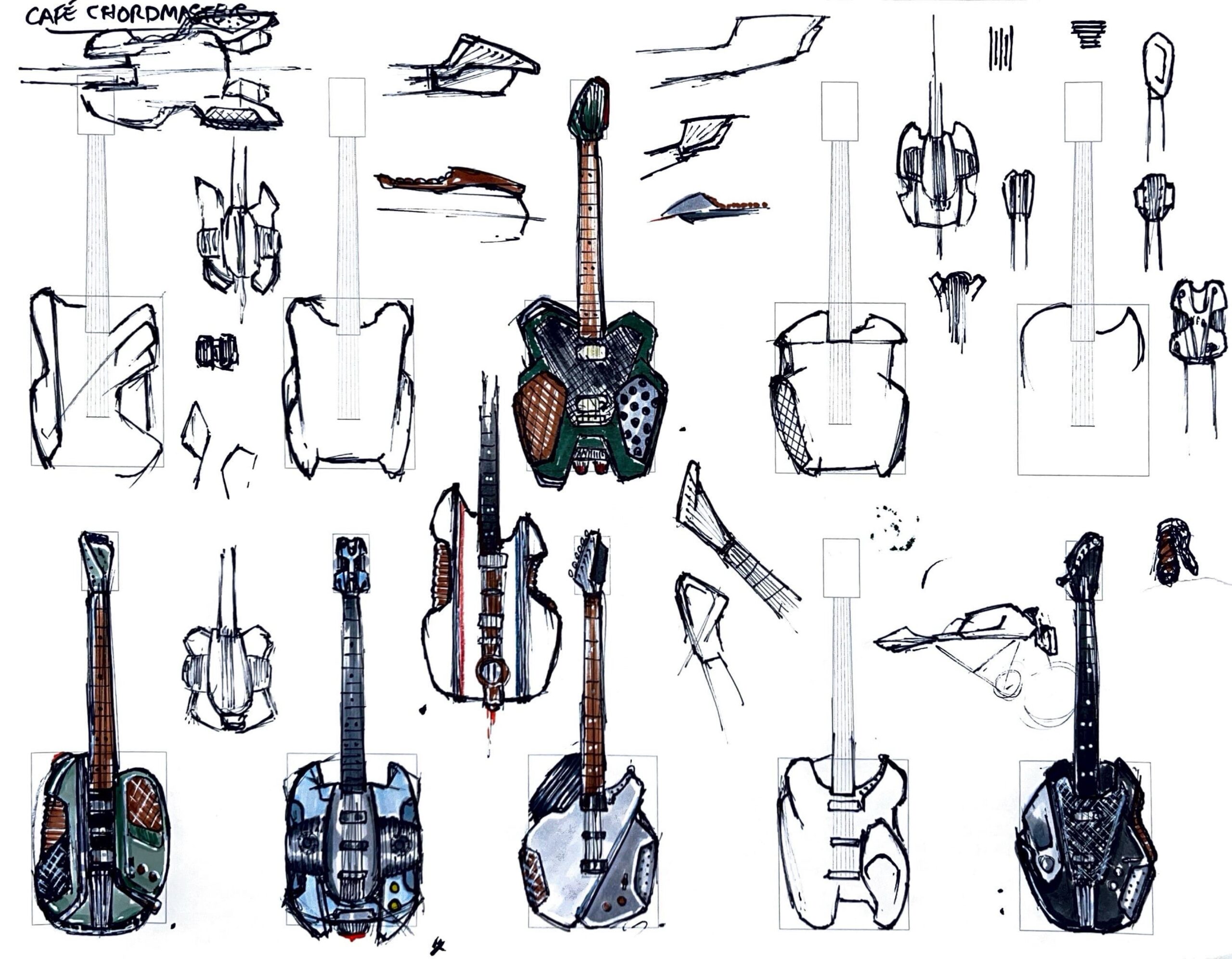

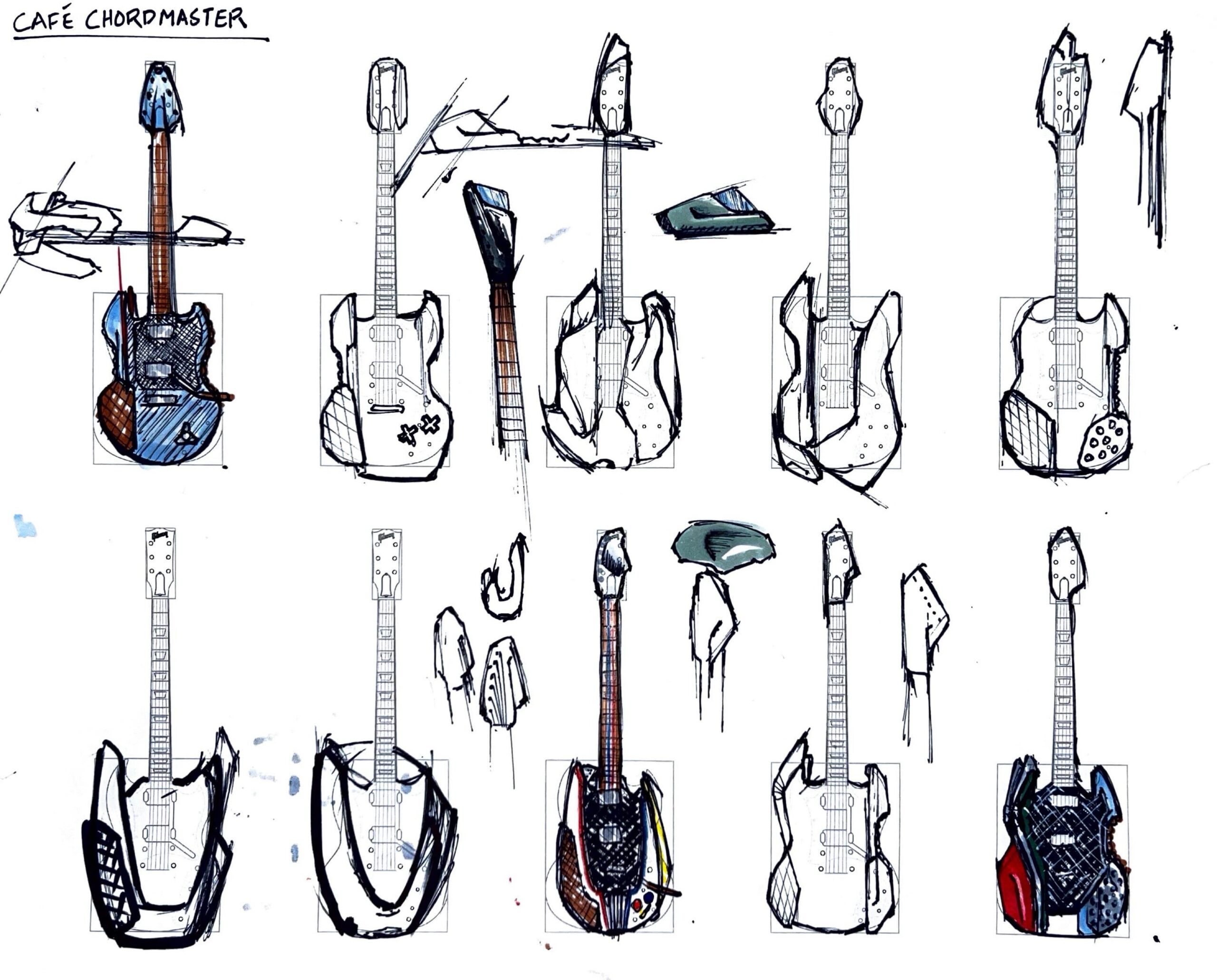

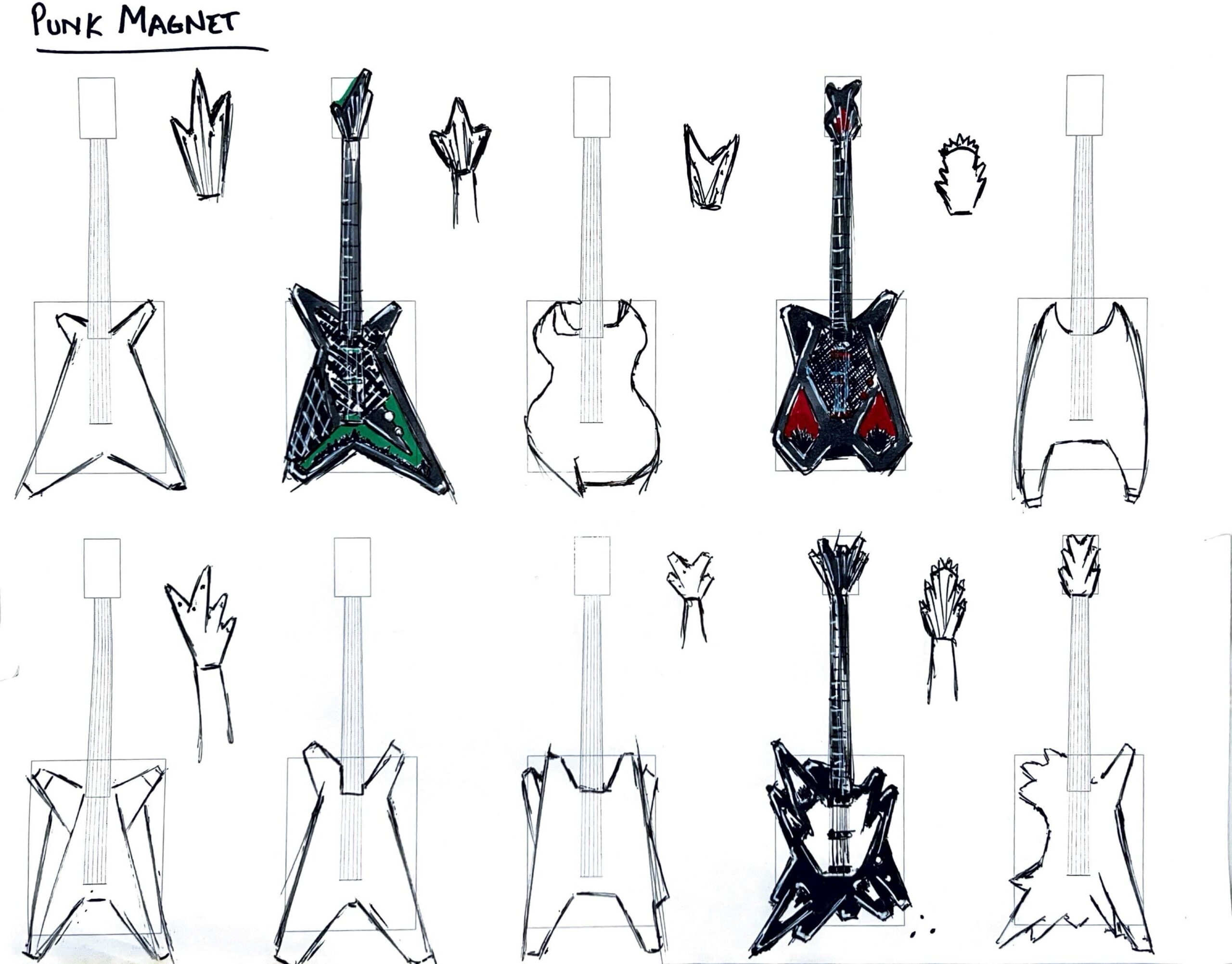

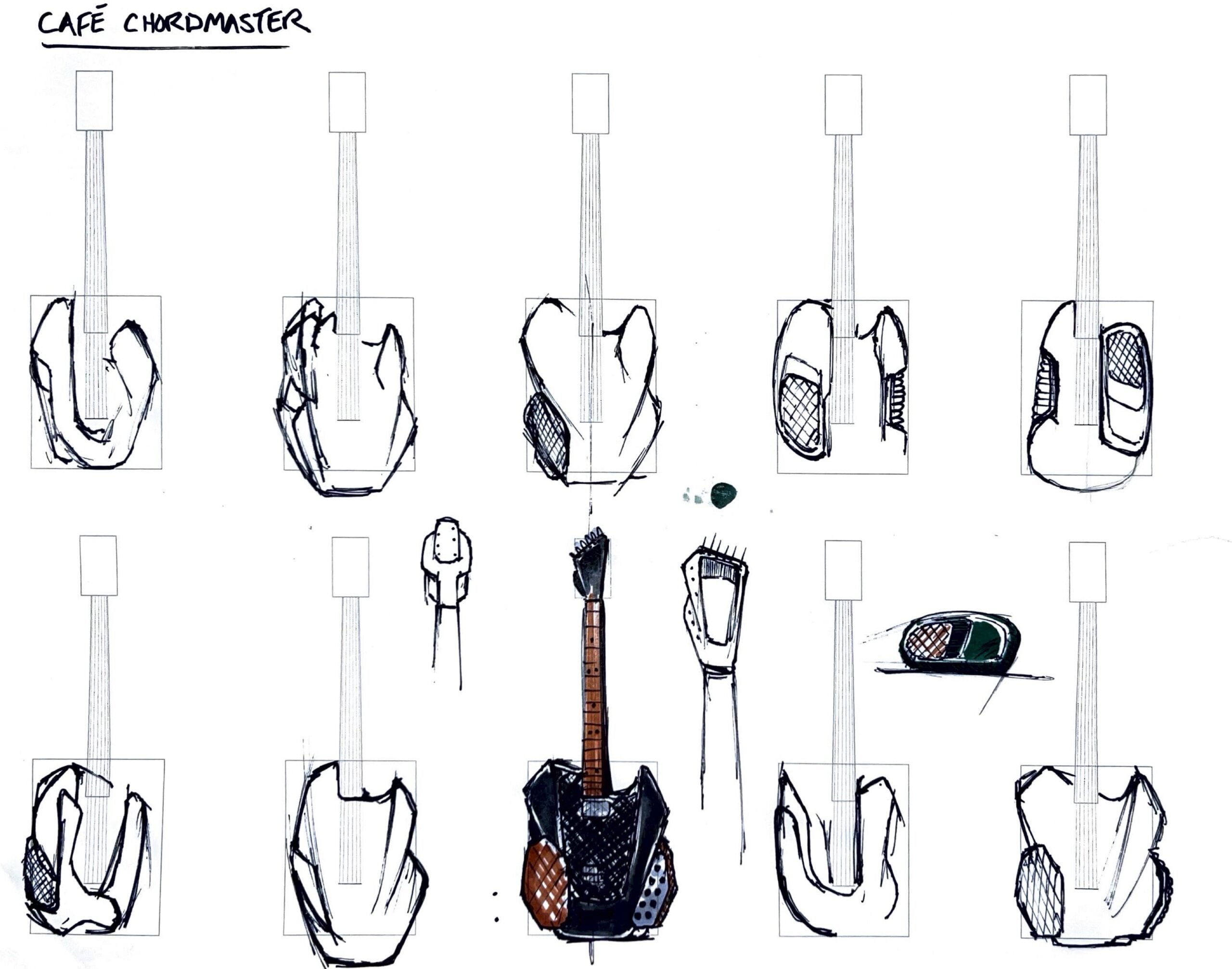

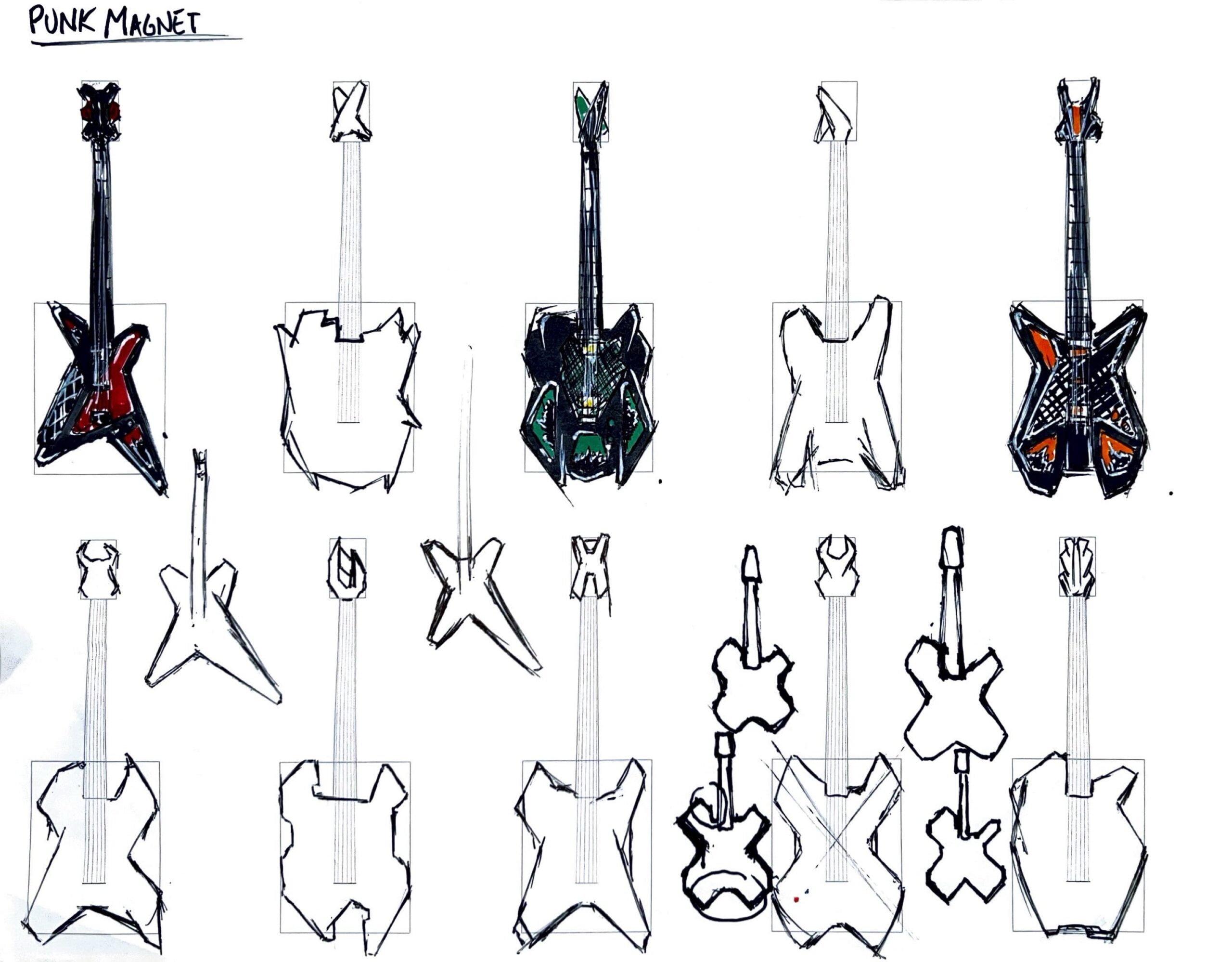

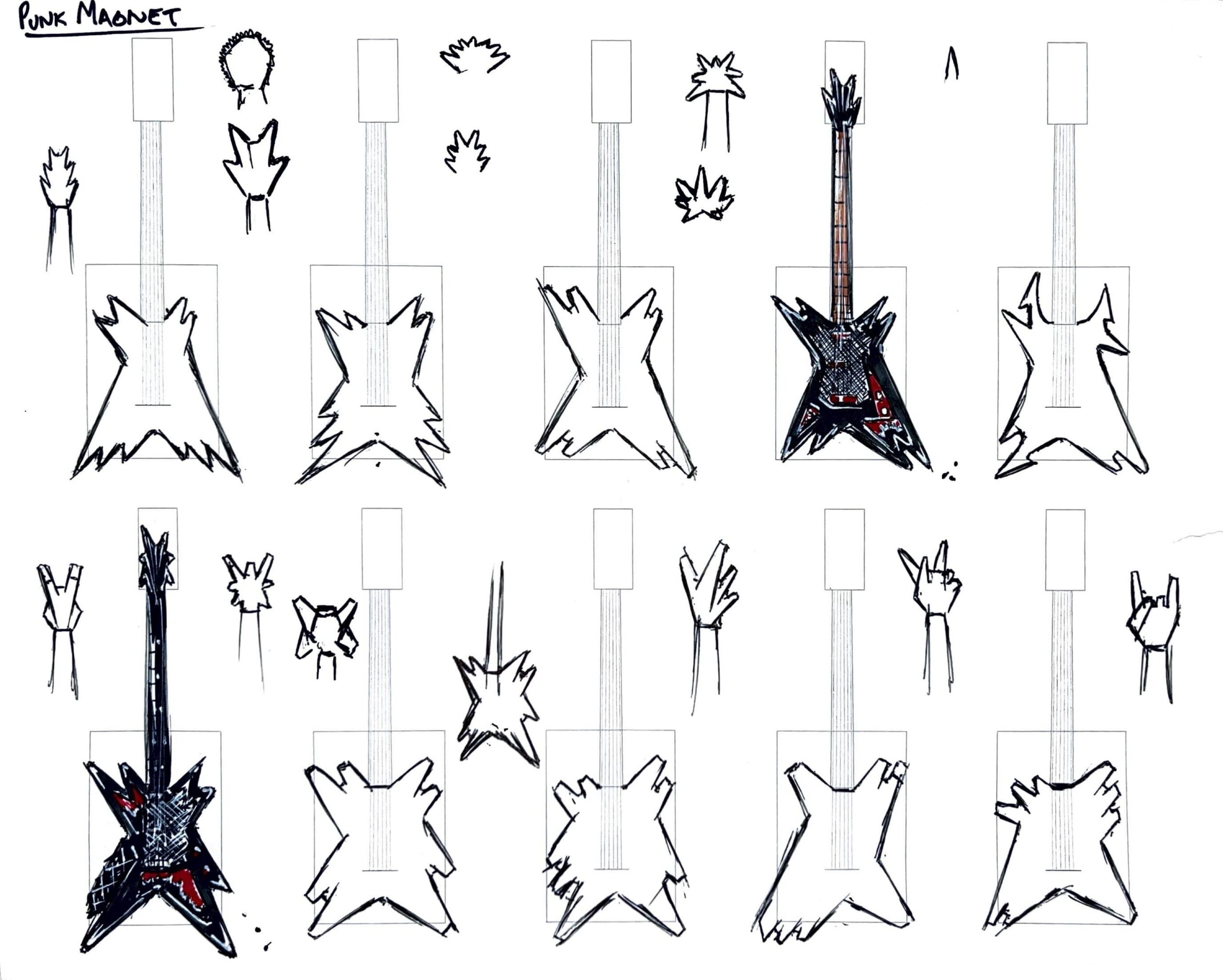

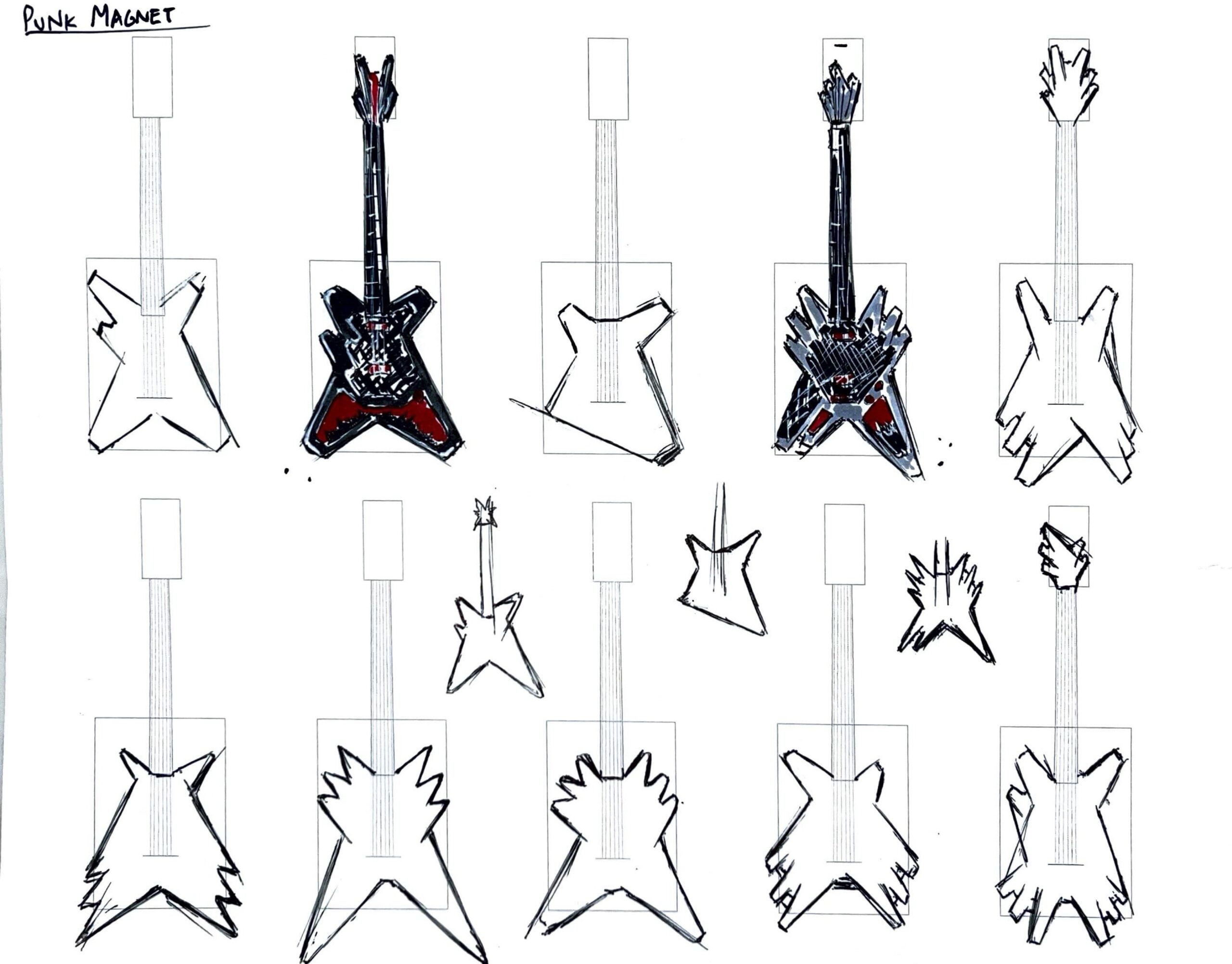

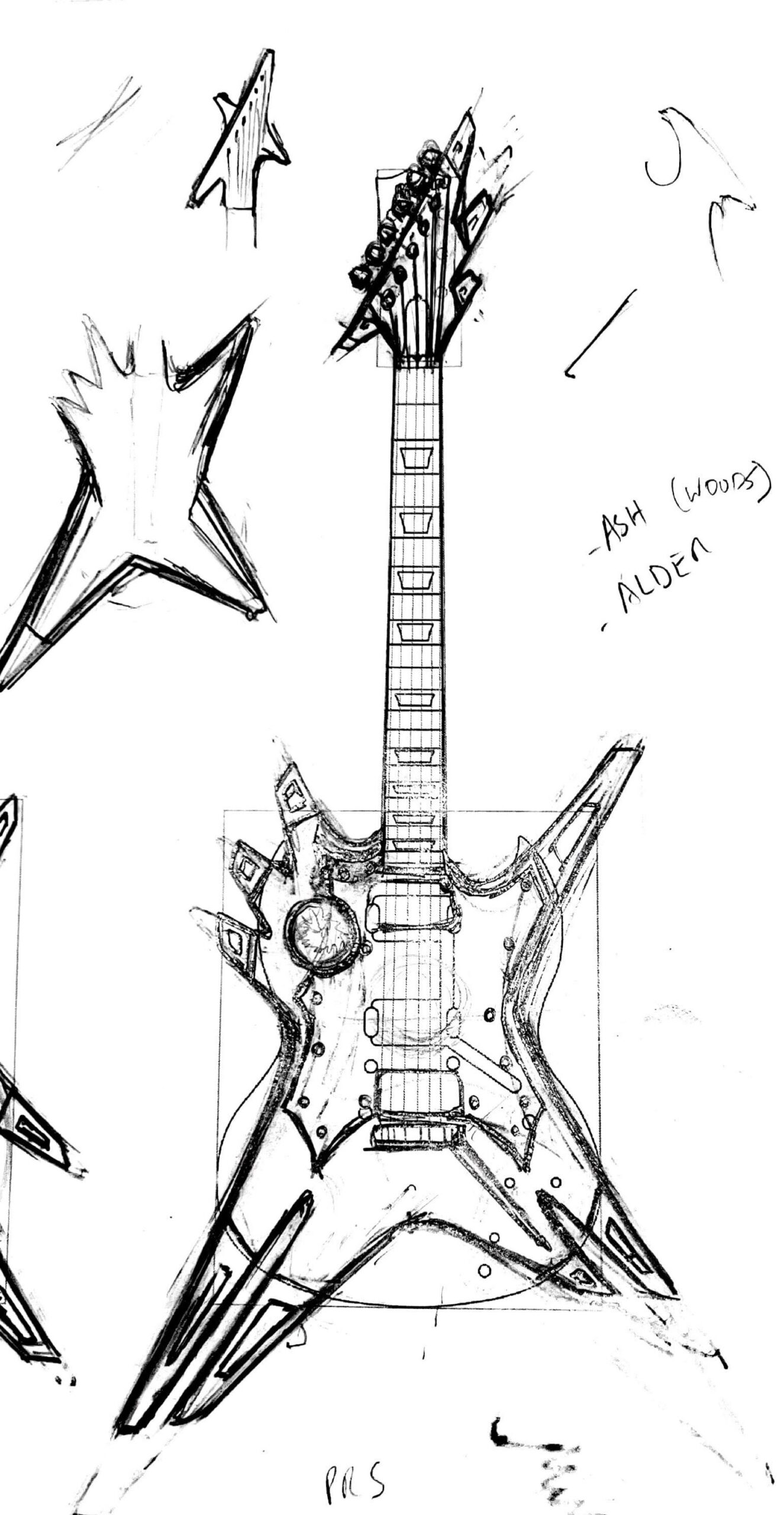

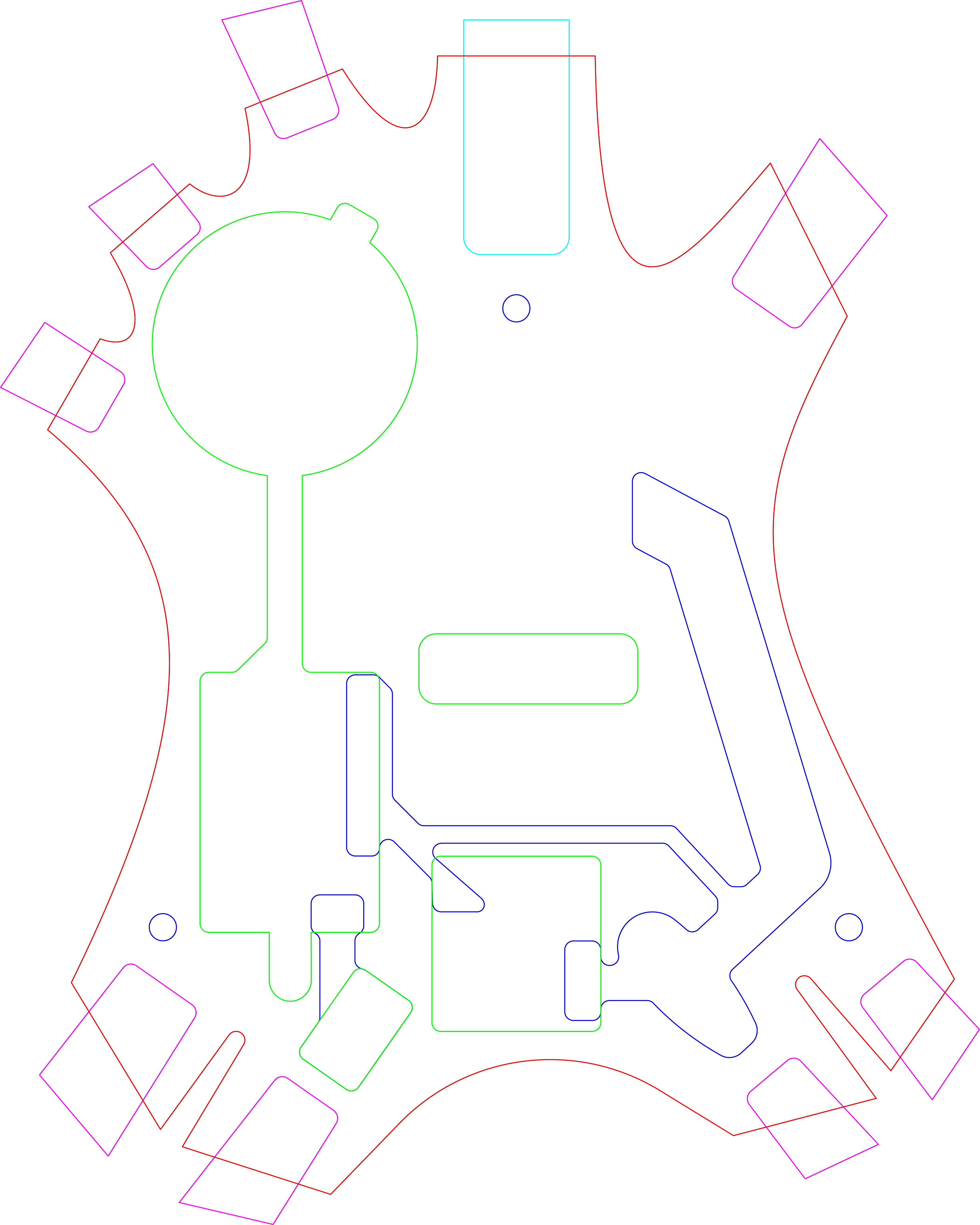

Form Exploration

Through multiple form and feature explorations, I was able to use the geometry of existing guitar bodies to find a shape that best reflects the theme and vision.

Given only two weeks to design, the final concept needed to be rapidly ideated to allow enough time for full-on fabrication.

Proportions and form were drawn on top of the classic Gibson SG body, where the removable tips allow the guitar to fit inside a standard carrying case

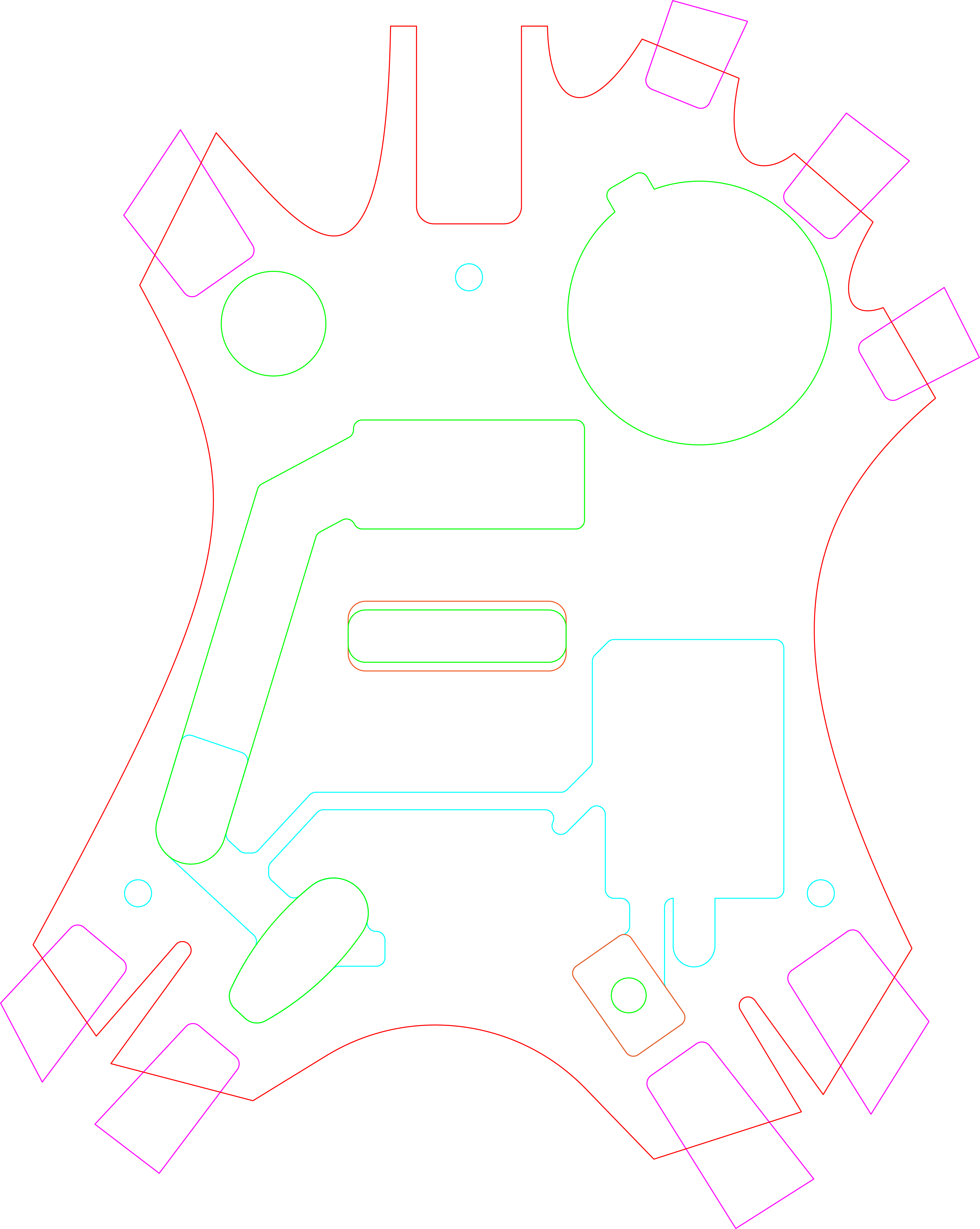

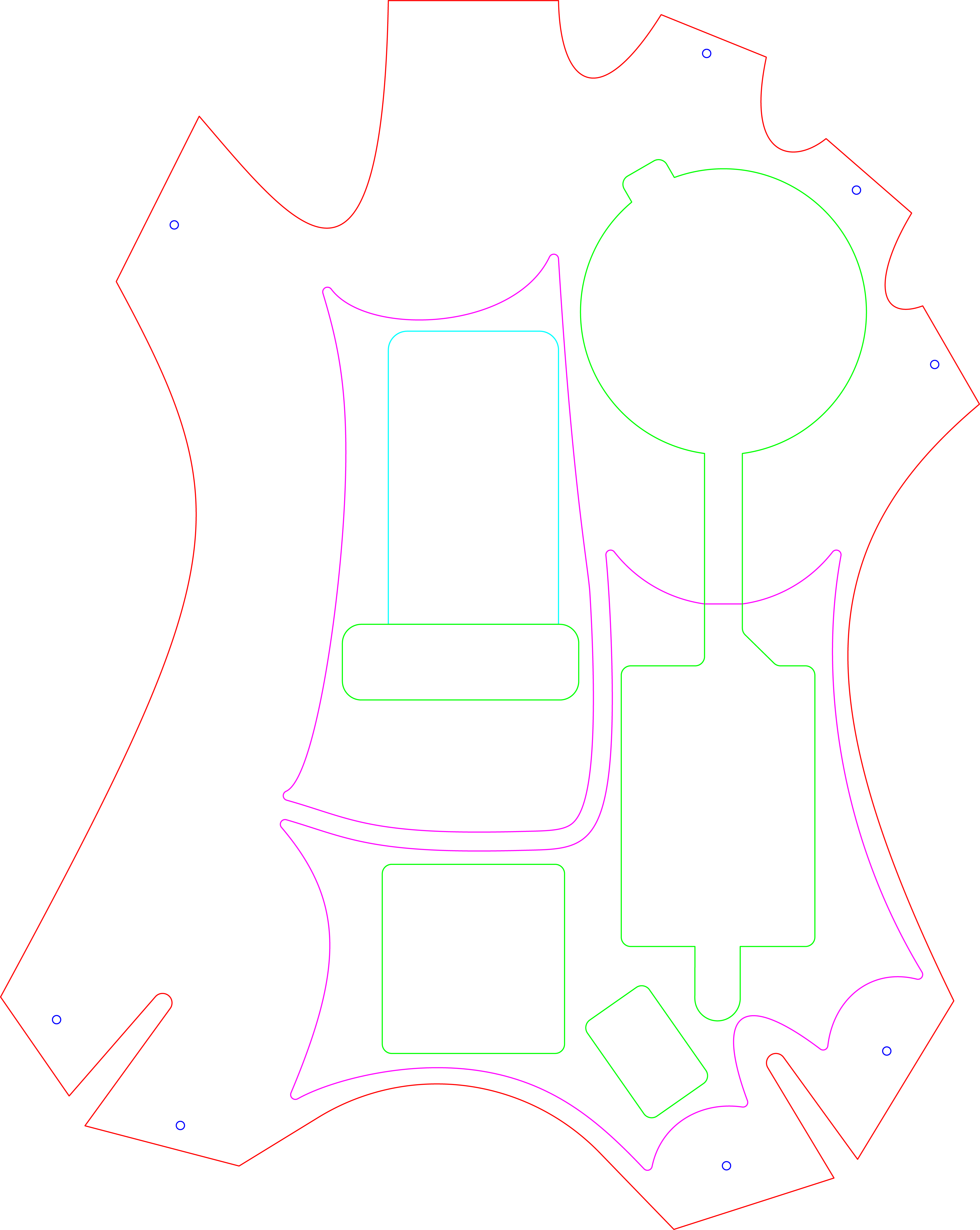

CNC Body

From CAD to CNC, the split-body design was translated from the computer to a tangible prototype.

By thoughtfully routing out numerous internal channels, concealing and installing wiring/components became seamless

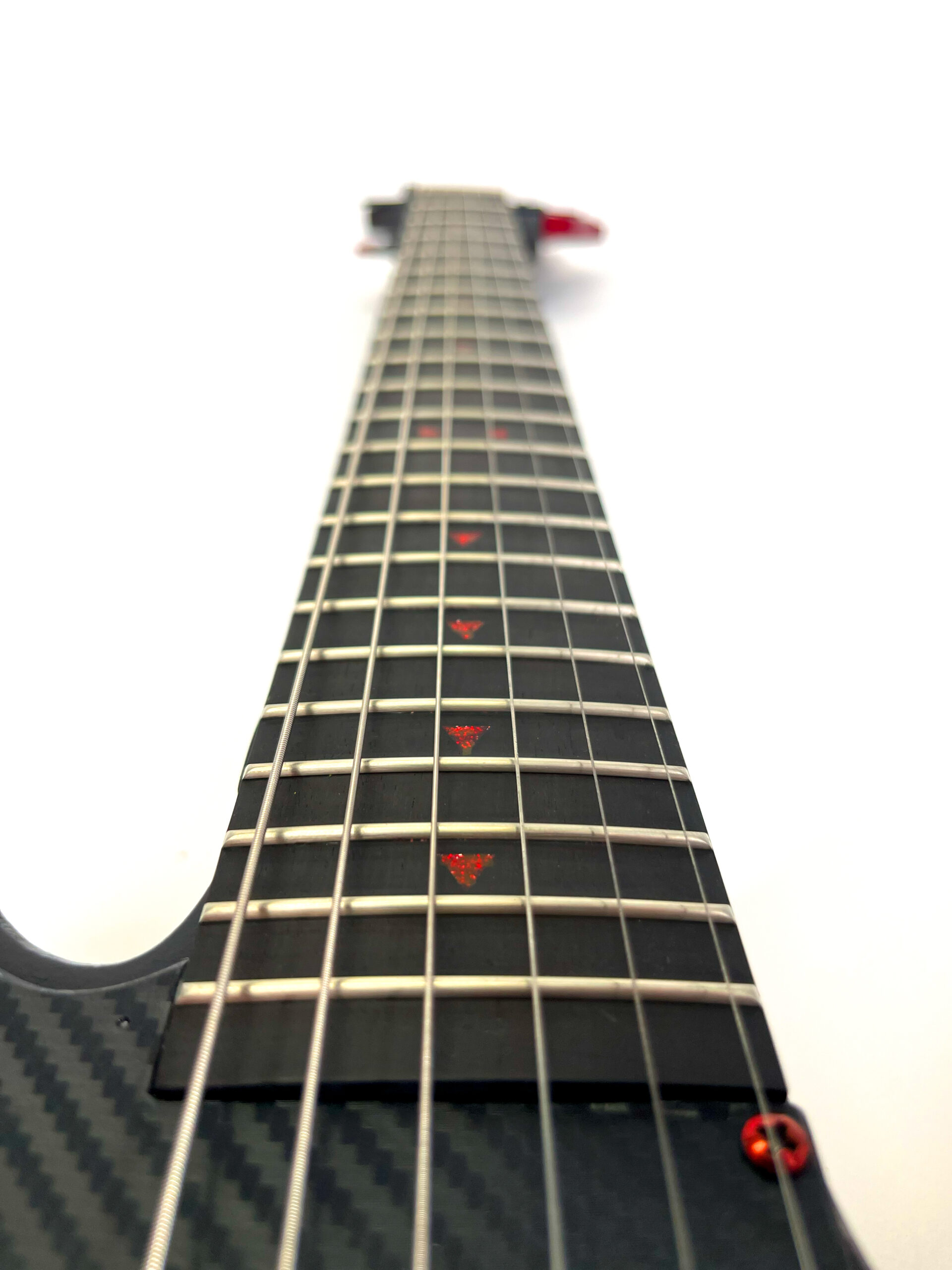

Modifying the Neck

Gibson Guitars was proud to provide us with several different neck stock pieces directly off their assembly line from their Nashville, TN factory

The most essential part of the guitar...

With so many precise and mathematical factors affecting the final sound quality of the instrument, extreme attention to detail - down to 1/100th of an inch - was required to adapt the Mahoghany bent neck to my design intent.

In line with the aggressive theme, I laser-etched custom fingerboard inlays before filling the Ebony material with eye-catching red epoxy resin.

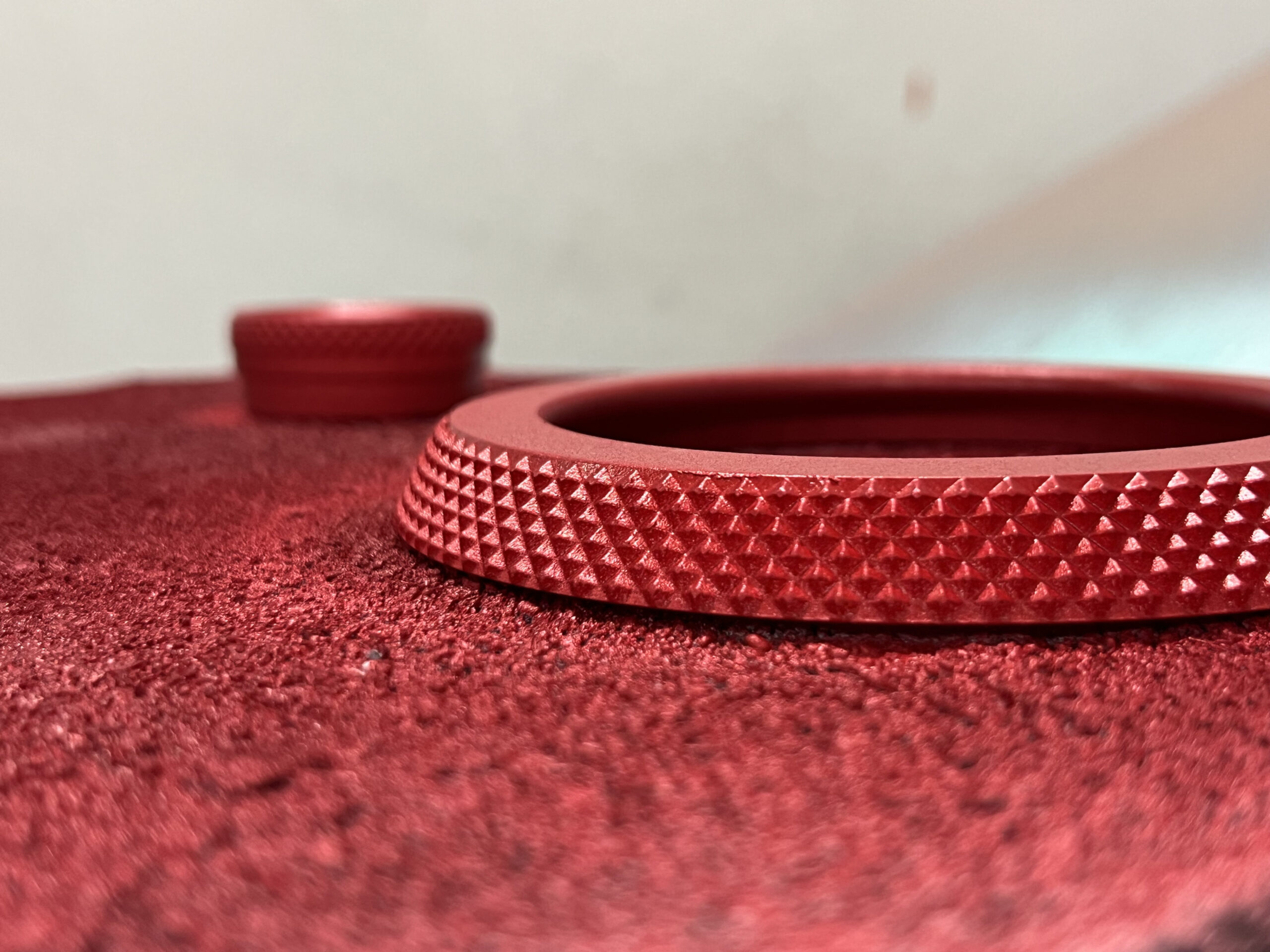

3D Printed Components

Removable and customizable tip inserts were implemented using a durable FormLabs SLA resin material, then painted using a metallic automotive paint/primer.

Painting

Hey there, this is the default text for a new paragraph. Feel free to edit this paragraph by clicking on the yellow edit icon. After you are done just click on the yellow checkmark button on the top right. Have Fun!

As the most popular consumer color pick, the instrument was meticulously coated with black lacquer, clear polycoat, and given a hand-painted red pinstripe on the neck.

Neck + Body

A clamshell design secures the neck joint on either side with pockets to fit the removable tip inserts.

Final Assembly

Andrew Helmly

awhelmly@gmail.com

(843) 834-9059

Selected Works

FretHaus Guitar DesignSenior Thesis

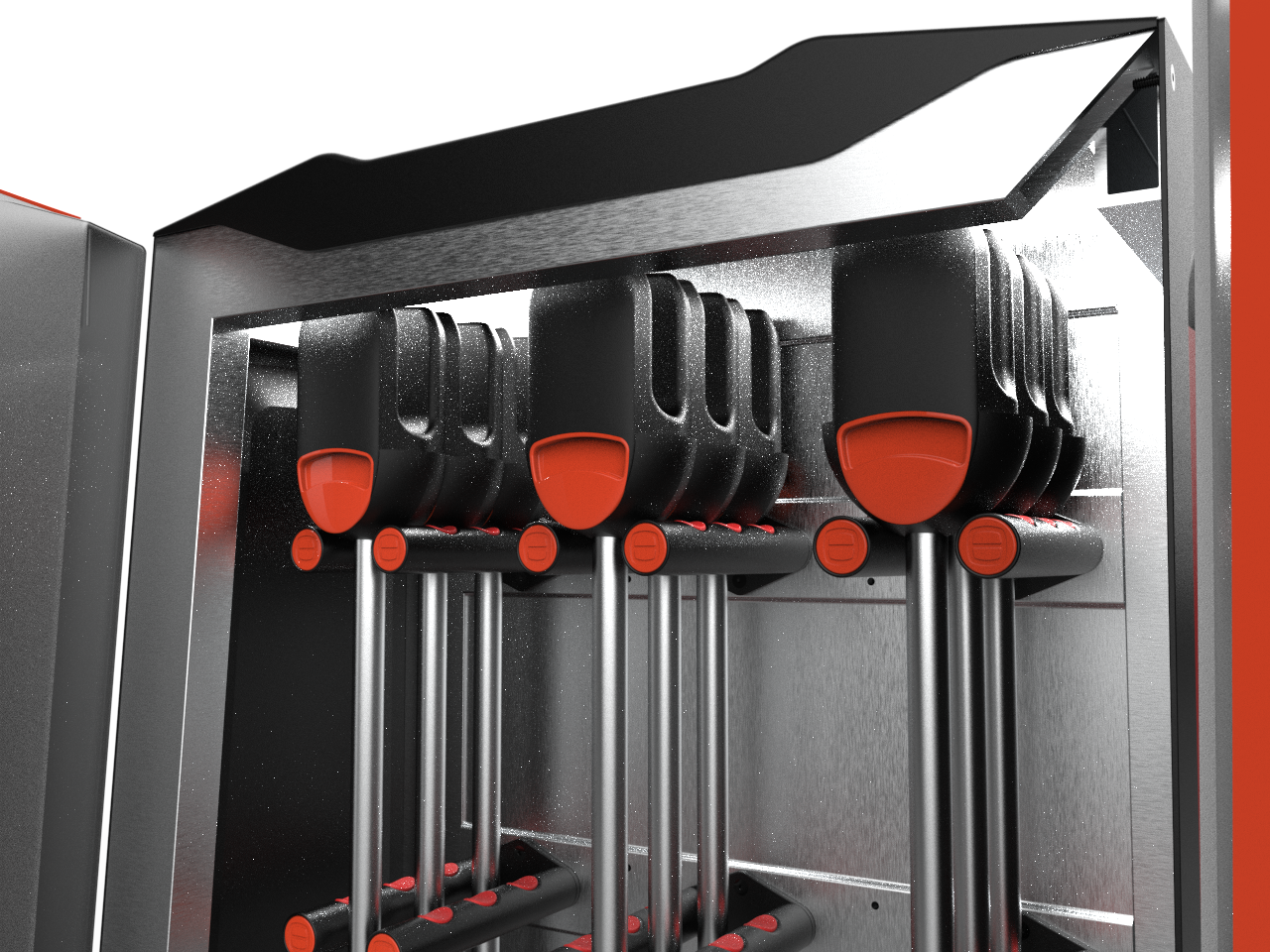

LesMills Bodypump: SaniRackWorkout Equipment Redesign Studio

ABC: Analog Beat ComposerTigerCage Competition Submission

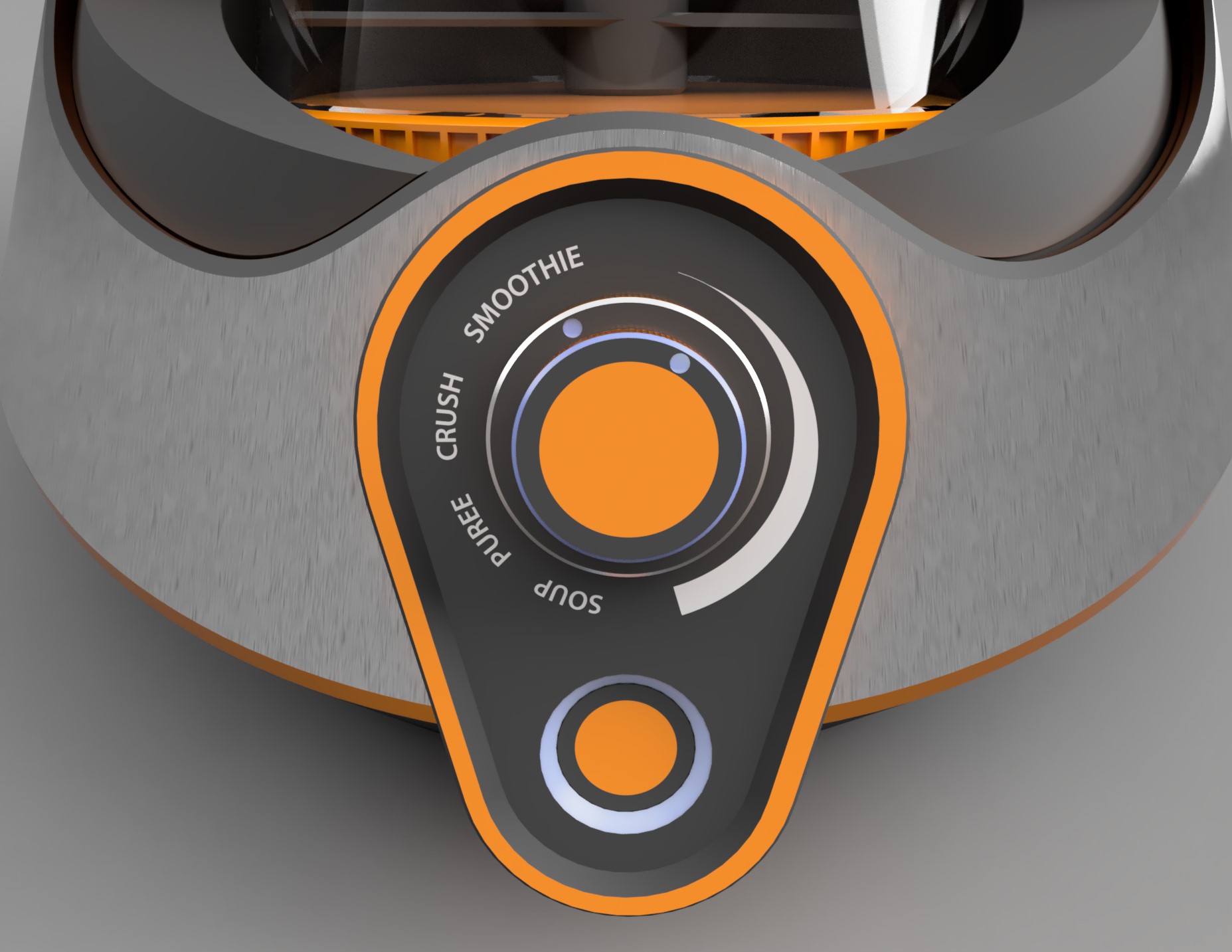

TiltMaster BlenderInside-Out: Kitchen Appliance Redesign

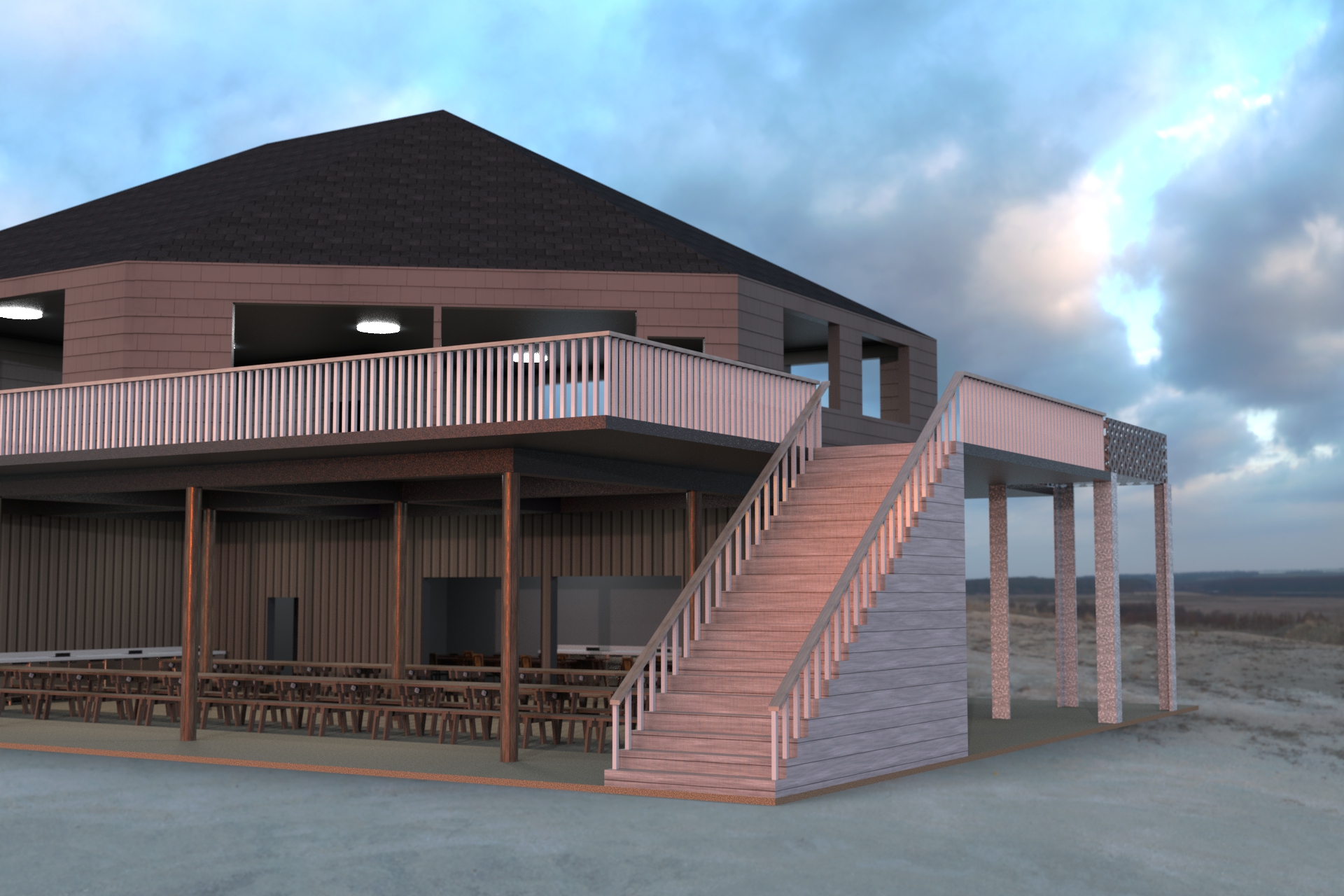

Dauphin Island Sea Lab: Research Facility DesignArchitectural Design

Yotrio Corp. Internship OverviewCorporate Design